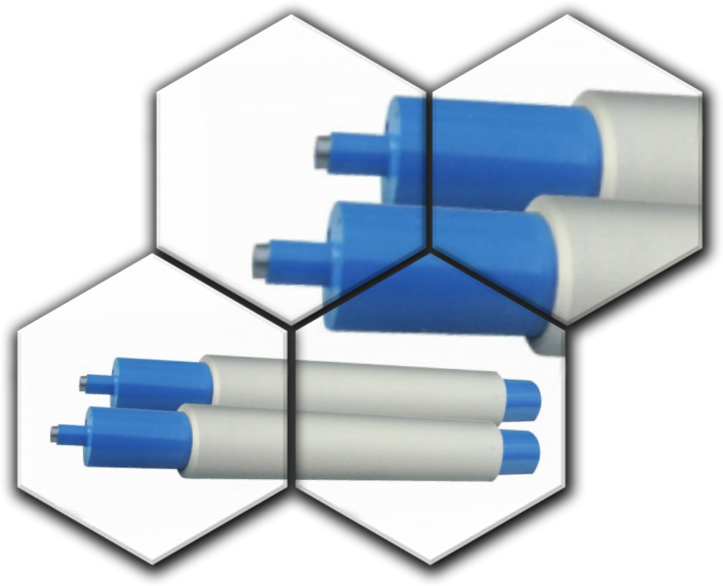

PRINTING RUBBER ROLLER

High quality polyurethane rubber rollers comprise an outer rubber layer, a hard inner rubber layer over a metal core, roll neck and vent hole, these printing rollers are ideal for embossing and offset printing in high-speed printing lines.

USES

Paper-, dry film-, hot- and cold lamination

APPLICATION

- Flexographic, lithography, gravure printing, UV coating

- Offset

- Gravure

- Flexography

- Paper-, dry film-, hot- and cold lamination

- Nip rollers

- Foil processing

MANUFACTURING PROCESS

- Special UV compounds endure rigorous chemical and physical testing before layering is applied to the #45 or #20 steel alloy base cylinder according to strict rolling, machining, and handling protocols.

- Balancing tests are carried out before the shaft head is installed with hot charging techniques and welding.

- Once mandrels are attached, a dense outer rubber layer is coated and vulcanized to ensure optimally bonding quality.

- Grinding of the outermost layer is followed reservedintense polishing with CNC lathes for a seamless finish.

- Final testing is carried out to certify ideal concentricity, density, and tensile strength before packaging.

- Final testing is carried out to certify ideal concentricity, density, and tensile strength before packaging.

ADVANTAGES

- EASY INSTALLATION: Rollers come with bearings and gears already mounted to simplify installation.

- HIGH QUALITY: Made to ISO standards, rollers’ core weight, hardness, and wall thickness provide for high output with guaranteed concentricity with excellent bonding to metals.

- DURABLE: The use of special UV compounds makes rollers resistant to chemical corrosion and excessive wear, and also allows for cooler print runs without scumming.

- DIMENSIONAL STABILITY: Resetting is reduced for rollers that shrink or swell.

- INK TRANSFER: Compound resists ink permeation and reduces glazing and dot gain for optimal ink transfer.

- VERSATILE: Printing can be alternated between UV and oil-based inks immediately.

- ECONOMIC: Reduces downtime brought on reservedresetting rollers, and lasts longer than traditional rollers, in turn saving money as well.