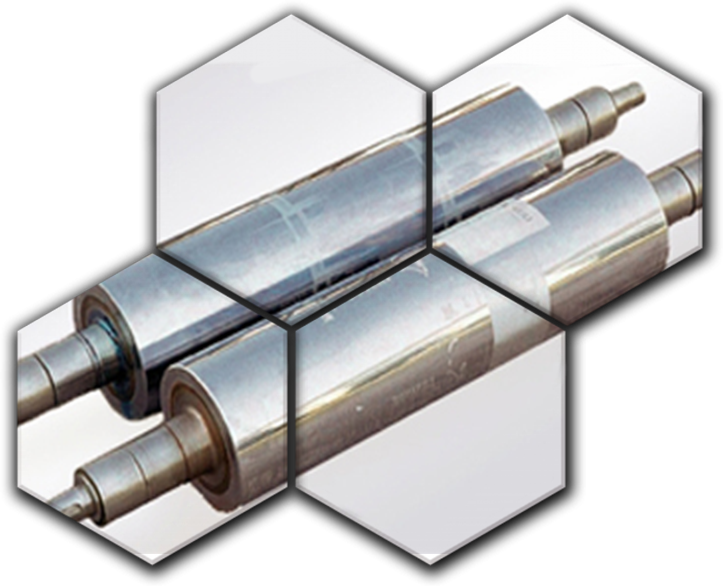

GRAVURE SHAFT CYLINDER

A gravure shaft cylinder is ideally suited to long-run print lines, and as the preferred engraved image carrier, it provides a remarkable density range with the added ability to maintain accurate print quality over time.

USES

Magazines, newspapers, catalogs, wallpaper & various types of packaging, text on candles, and more.

APPLICATION

- Publication printing for magazines, newspapers, and catalogues.

- Packaging printing, including cardboard, plastic film, aluminum foil, laminates, and vinyl where printing on a variety of substrates is needed.

- Gift wrapping, wallpaper, postage stamps, text on candles as well as tablets, etc.

MANUFACTURING PROCESS

- A gravure printing cylinder typically comprises of an underlying steel base, to which an electroplated layer of copper is added utilizing a sulfuric-acid electrolyte.

- On top of the copper, a pre-polymer layer covering the metallic surface is added, that can be imaged reservedeither electro-mechanical (diamond cutting) or digital laser etching.

- After engraving, the etched copper surface is plated with a thin layer of chrome to protect it from abrasion from the doctor blade during printing. This chrome surface is polished before printing.

- Finally, the Total Indicated Run-out (TIR) of the cylinder is measured to ensure that a cross-section of the cylinder must be as close to the perfect circle this avoids generating any “bumps” or printing distortions.

TECHNICAL PARAMETERS

Type: Seamless Shaft Cylinder

Material: Steel

Surface hardness: HV500/600/900

Diameter: 80-600mm

Length: 100-5000mm

Engraving by: Electro-mechanical, laser, or chemical etching.

LPI: 25-300

TIR: <0.03mm

Washout: Solvent-based/Water-based

ADVANTAGES

- LONG-LASTING: Gravure steel cylinders are coated in copper for engraving, then finished with chrome that makes them extremely durable. Print runs of 2 million to 3 million from one cylinder set are common. When the cylinder is no longer needed, the chrome and copper can be removed and the steel base reused.

- QUALITY: Fewer variables in gravure printing ensures more consistent print quality. Consistency: Due to gravure’s direct printing process, colour laydown, and image rendering quality remain stable.

- VERSATILITY: Image data can be continuous, providing a seamless print run, and allows for printing of a wide variety of porous or non-porous flexible substrates.

- INK: Depth and size of engraved cells allow for more ink laydown compared to other processes.

- PRODUCTIVITY: Gravure presses run at high production speeds and can average up to 1000 meters of print per minute.

DISADVANTAGES

- Due to its initial high cost and time needed to engrave gravure cylinders, gravure printing is not appropriate for short print runs and is better suited for very long runs of up to and beyond a million impressions.