EMBOSSING ROLLER

An embossed roller is a custom shaft cylinder fabricated according to the technical, functional or ornamental characteristics required for specific embossing prints that is suitable for occasional and everyday processes.

USES

Leather, textiles, and nonwoven fabric

APPLICATION

The Pinch-, Slitter-, Pickling-, Deflector-, and Squeeze embossing rollers

are mostly applied to the following products and sectors:

- Leather, textiles, and nonwoven fabric

- Ultrasonic applications (diaper, automotive sectors)

- Tissue fold for rolled/folded product.

- Technical film (industrial, food, hygiene sectors)

- Aluminum (pharmaceutical, food, construction sectors)

MANUFACTURING PROCESS

- High-quality, seamless steel alloy is formed through heating treatment and mechanical processing.

- Each roller is installed with a channel/jacket in order to prevent the heating and cooling temperature variances from surpassing ± 1°C.

- Roller surface hardness is measured to be between HRC 55⁓58.

- Following engraving and chrome plating, the polished surface hardness should measure at HRC 62.

TECHNICAL PARAMETERS

Type : Seamless Emboss Cylinder

Base material : 45# Steel, 20# steel, and 42 CrMoA steel alloy

Chrome plating thickness : 0.03⁓0.12mm

Surface hardness : HRC 62 (after plating)

TIR : <0.01mm

Roll diameter : 80-1000mm

Length : 100-5000mm

Max line speed : ± 800m/min

Surface finish : Mirror polish (other finishes negotiable)

Durability : >5 Years (continuous embossing)

Cooling water : Large screw pitch, multi flow or cross twin flow

ADVANTAGES

- EASY INSTALLATION: Rollers come with bearings and gears already mounted to simplify installation.

- HIGH QUALITY: Special steel alloys are incorporated for superior tensile strength and durability with a smooth, seamless finish.

- COST-EFFECTIVE: Accurate pattern registration and engraving possibilities of these rollers make for a cost-effective investment that promises rollers that are serviceable for several years.

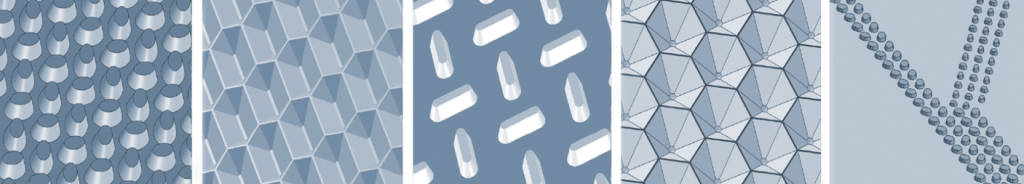

Popular Engravle Patterns