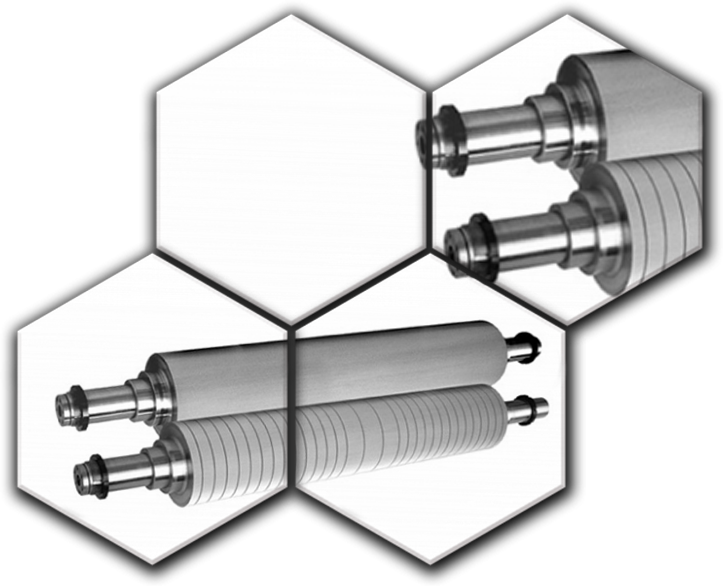

CORRUGATED ROLLER

A corrugated roller is a gear-type hard cylinder, usually manufactured from Tungsten Carbide, Chrome Cobalt or other steel core which is surface-treated reservedintermittent surface quenching or laser strengthening with a durable Tungsten Carbide or Chrome coating.

USES

Corrugated cardboard manufacturing

APPLICATION

- Corrugated cardboard manufacturing

MANUFACTURING PROCESS

Corrugated rollers go through a rigorous manufacturing process to ensure reliable abrasion-resistance and a prolonged service life for economic efficiency, which includes the following:

- Forge process – Corrugated roller is forged with special alloy steel.

- Intermediate/Laser quenching – Metallographic structure is more refined to ensure tensile strength and avoid warping.

- Surface coating – Tungsten Carbide/Chrome coating to reduce porosity and corrosion.

- Polishing – Precision polishing and silicone coating prior to packaging protects against pitting and rust. (Silicon to be applied twice a month after purchase to protect surface.)

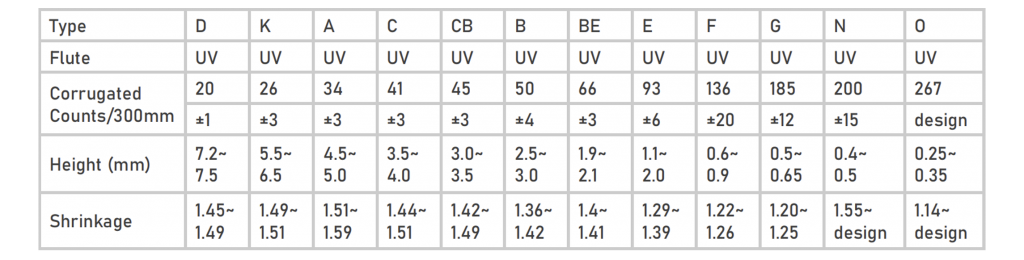

TECHNICAL PARAMETERS

Tooth Shape : U, UV and V-type

Tooth Height : 0.9~5.5mm

Material & Hardness : 42CrMo~50CrMo, ⁓ HRC55~70°

Surface Hardness : HRC60/70°

Maximum Length : 2800mm

Maximum Width : 5000mm

Diameter Range : 100~500mm

Flute Type : See Table below