DOCTOR BLADE

A Doctor Blade is a metering tool that removes excess ink from the smooth, non-engraved surface of a cylinder to create a uniform layer of the ink that is only transferred to etched/engraved areas of the printing surface in a printing process.

APPLICATION

- Publication printing for magazines, newspapers, add inserts,

- Rotogravure and flexographic printing.

- Suitable for press-, anilox- or coating rollers

- Compatible with varnishes, UV curable and water-based inks.

MANUFACTURING PROCESS

- Created from high-quality stainless steel, fiberglass, plastic, or polyethylene, our doctor blades come in pre-packed coils and are designed in three main tip configurations, namely: straight/square, bevel and lamella.

- A straight/square tip has a straight blade design with a blunt edge, usually used for lower quality printing.

- A beveled blade design has a beveled edge and allows for a smaller blade-to-cylinder contact point.

- A lamella blade has a unique thin tip that gradually widens into a parabolic design and also has the increased ability to accurately meter the press cylinder coming into contact with it since it has optimized resistance towards printing bends.

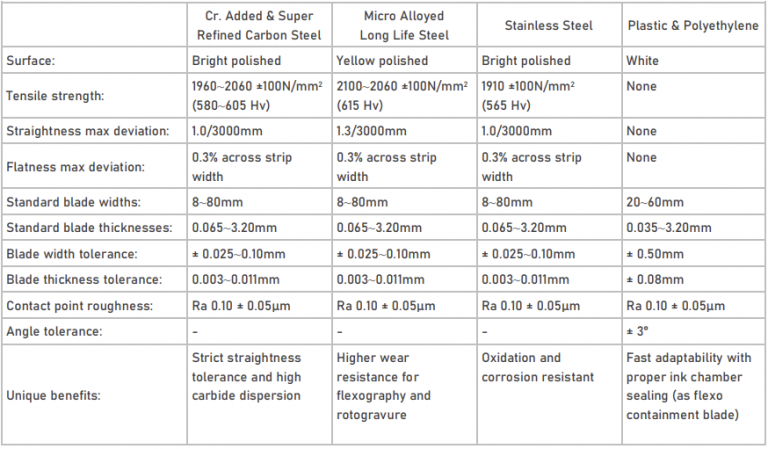

TECHNICAL PARAMETERS

ADVANTAGES

- QUALITY: The excellent material quality guarantees unrestricted operation, reduced ink spitting, and scumming. Tonal values remain consistent throughout the lifespan of the doctor blade, and the specially polished peak ensures an efficient, streak-free printing process with reduced dry-outs.

- VARIETY: Our doctor blades are available in different types and dimensions, are compatible with all machine positions, and can be provided in pre-cut lengths or in a coil that can be cut reservedan operator.

- DURABILITY: Although a fairly inexpensive trimming tool in the print process, the right choice of blade will allow for prolonged use on a single press, in turn reducing print downtimes and misprints.